In the rugged, remote environments of Australia’s mining heartlands—Queensland, New South Wales, South Australia and Western Australia—every minute of uptime counts. A stranded haul truck or drill rig can cost tens of thousands of dollars per day in lost productivity, not to mention the safety risks of unscheduled maintenance amid rocky terrain and volatile weather. That’s why, at Reel Tech, we specify Hannay hose reels for nitrogen tyre inflation: a combination of industry‑proven inert gas inflation and rock‑solid American manufacturing that delivers maximum reliability, minimal maintenance and years of uninterrupted service.

In the rugged, remote environments of Australia’s mining heartlands—Queensland, New South Wales, South Australia and Western Australia—every minute of uptime counts. A stranded haul truck or drill rig can cost tens of thousands of dollars per day in lost productivity, not to mention the safety risks of unscheduled maintenance amid rocky terrain and volatile weather. That’s why, at Reel Tech, we specify Hannay hose reels for nitrogen tyre inflation: a combination of industry‑proven inert gas inflation and rock‑solid American manufacturing that delivers maximum reliability, minimal maintenance and years of uninterrupted service.

While conventional compressed air is readily available, it contains moisture and oxygen—both of which accelerate tyre aging and foster unpredictable pressure changes. Nitrogen offers three critical advantages:

-

Stable Pressure Retention

Nitrogen molecules are larger than oxygen, reducing permeation through rubber sidewalls. This means that tyre pressures remain within optimal ranges for longer periods, minimizing the need for frequent re‑inflation or emergency top‑ups deep in the field. -

Moisture‑Free Environment

Unlike air, nitrogen is supplied dry. By eliminating internal moisture, nitrogen prevents corrosion of internal tire components and rim assemblies—vital in humid or coastal mining sites, or where temperature fluctuations are severe. -

Reduced Oxidation

Oxygen in compressed air can oxidize rubber compounds, causing micro‑cracks and accelerated tyre deterioration. Nitrogen’s inert nature extends tyre life by preserving compound integrity, which is particularly important for large off‑road mining tyres costing tens of thousands each.

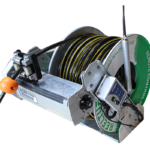

The Case for Hannay Hose Reels

Supplying nitrogen into every axle group requires reliable hose management. Hannay Industrial reels have been the gold standard in American hose‑reel engineering since 1933, and for good reason:

-

Unrivalled Build Quality

Every Hannay reel is fabricated from heavy gauge steel or corrosion‑resistant aluminum, powder‑coated for UV stability and impact resistance. These reels shrug off harsh sunlight, abrasive dust and chemical wash‑downs common in mining yards. -

Industry‑Proven Durability

With simple mechanical designs—solid brass swivel joints, precision‑machined bearings and minimal internal seals—many Hannay reels operate maintenance‑free for over a decade. In remote sites where workshop hours are precious, this translates to fewer reel rebuilds or unscheduled repairs. -

Smooth Retract and Consistent Pay‑Out

A calibrated spring‑drive system balances hose tension, preventing snap‑backs and kinking. Operators can deploy hoses up to 30 metres without strain, then retract them safely with a controlled, wobble‑free motion—reducing operator fatigue and tripping hazards in busy work areas. -

Customisable Options

Hannay offers a range of hose IDs, lengths and swivel configurations. Whether you’re feeding 1/4″ nylon tubing for a quick farm‑tire inflation gun or a 1″ steel‑braided hose for high‑volume, high‑pressure back‑of‑truck manifolds, there’s a reel tailored to your pressure requirements. -

Made in the USA, Backed by Local Support

Each reel carries the “Made in USA” hallmark of quality craftsmanship and is distributed here in Australia through our strategic engineering partnership. Local stocking means faster deliveries to Gladstone, Kalgoorlie, Port Hedland and beyond, with technical support and replacement parts on hand.

Return on Investment: Uptime, Savings and Safety

When you choose a Hannay hose reel for nitrogen inflation, you’re not just buying a piece of equipment—you’re investing in:

-

Less Downtime

With years of dependable service between maintenance intervals, fleet managers can schedule planned shutdowns around operational needs, not reel failures. -

Lower Maintenance Costs

Beyond the initial investment, upkeep is minimal: an annual wipe‑down, a quick visual inspection of swivels and bearings, and occasional lubrication of moving parts. No specialized tools or in‑field rebuild kits are required. -

Enhanced Worker Productivity

Fast, tangle‑free hose deployment means your maintenance crews can inflate multiple tires in less time, allowing them to get back to other critical tasks. -

Improved Safety

Controlled hose retraction and robust construction mitigate trip‑and‑fall hazards and eliminate sudden “snap‑back” injuries, which are all too common with poorly engineered reels or improvised hose management solutions.

Conclusion

In Queensland’s sprawling coal fields, New South Wales’ opal country, South Australia’s copper mines and Western Australia’s iron‑ore countryside, reliability is non‑negotiable. By combining nitrogen tire‑inflation best practices with Hannay’s legendary hose‑reel engineering, Reel Tech delivers a turnkey solution that maximizes fleet uptime, reduces operational costs and ensures the safety and efficiency of your workforce. Contact us today to discuss how we can deploy custom Hannay hose reels at your site—because in mining, every hour counts, and every detail matters.

By ReelTech Editor | May 29th, 2025 | Hose Reels - Mining - Quarry