A recent and large project undertaken by Reel Tech’s experienced design and fabrication team, involved a brief from one of Australia's largest mining companies, requiring a high level of engineering design expertise to solve the customer’s existing hose handling problems with their existing outdated and older hose storage reeling systems.

The customer initially enquired regarding problems onsite with their existing reel, in relation to not only the type of reel, but the way that the reel operated with the hose they needed to use, to convey their particular fluid. It is a common mistake to presume that one reel will suit multiple applications, while this is true for some reels and applications, it is not uniformly so, as all hose and cable will both wrap and act differently under various conditions, which can include, operating pressure, outside temperature, whether the hose is being pulsed via a pump or even the weight of the hose itself as well as the direction it is being paid out and in i.e. vertical or horizontal, on an angle and so forth.

The customer in question had a critical application where the reel had to work whenever It was needed at a moments notice, and even more importantly that this was a single person application for that section, therefore, when required, the reel had to pay out and rewind without fail. It was found that the reeling system extant, in conjunction with the hose type, bend radius and operating temperature, as well as the constant on and off operation, meant that the hose was constantly bunching up whilst travelling and making it quite difficult to reel out; requiring consistent human intervention, which then affected other operations in that area, causing a delay and bottleneck.

Ezi-Deploy™' - A fully automatic hose declutching system to safely and effortlessly handle hose reels with minimal drag resistance.

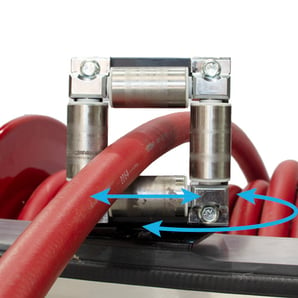

In consultation with the customer, Reel Tech suggested conducting some trials on a mock-up reel with a representative sample of the hose type that they needed to use; and found that a single wrap style (mono-spiral wrap) hose reel design, with Reel Tech's 'Follow Me Hose Guide', would prove to be more effective in combatting their hose-spool bunching and ultimately binding up. However due to the nature of the application and the size of the hoses used on these large service reels, there were no standard off the shelf reels available locally, therefore based on the trials undertaken, Reel Tech was commissioned to design and construct a custom reel solution, based on the mock up's undertaken, that could offer them the right solution.

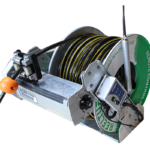

These reels were supplied with custom hydraulic drives, and enclosed safety panels that can be easily removed in the field for instant service access if required. With a smaller foot print, the reels took up less space on their work platform and have re-introduced a higher level of safety, productivity and reliability to their mine site.

Follow Me Hose Guide - A market leading multi-directional swiveling hose guide allows flexible use at any angle, a hose handling solution that reduces hose jam and damage.

After further discussion with the client on their exact requirements, Reel Tech developed a unique custom hose reel design, possibly a world-first, to meet their specifications which has been derived from its industry leading purpose built heavy duty mining reels called the Pit Bull™ mining series reeling technology.

The Pit Bull™ reels are manufactured in Australia with hot dip galvanised frame and disc components to reduce corrosion and the need to repaint reels during service life; and with Reel Tech's patented direct drive, reduced speed, torque gearbox and full flow hub, stainless fasteners and hose guide as standard.

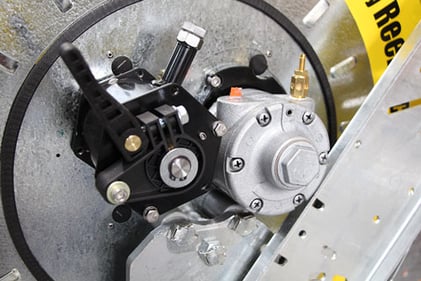

Most people are not aware that Pit Bull™ reels are designed and as standard are supplied with a patented quick change hub technology, this technology allows an operator to quickly change hose sizes and diameters without the need to change the entire reel, allowing for quick field upgrades and off the shelf solutions where available.

Pit Bull's latest permutation, the Pitbull SR - The SR series now includes Reel Tech's innovative 'Safe-R-Reel' rewind control system, ensuring a controlled speed during rewind while minimizing injuries and hose damage.

When designing new innovations, Reel Tech’s core focus is on the ease of use and handling safety. Pit Bull™ reels can be integrated with a gearbox called Ezi-Deploy™. This is an auto declutching system that allows for easy deployment with the lowest resistance, thus reducing operator strain injuries and excessive force that can prematurely damage equipment. With no levers, buttons or electronics required, operator can simply pull and go.

Reel Tech has delivered numerous custom solutions from narrow reels for smaller spaces to fully automatic oversized reels for all sizes and applications, as well as operating environments. For information about custom solutions, contact the team today.

By Stuart Morgan | October 14th, 2022 | Hose Reels - Mining - Quarry, custom hose and cable reels