A reel that works as hard as you do may require regular maintenance. For over 85 years, Hannay's reels have been the industry standard—not just for their exceptional workmanship and longevity, but also for their ease of maintenance, built-in safety measures, and easy repairs, even on the most difficult job sites. Continue reading to discover more about our maintenance-friendly reels and our video resource collection, which is packed with service instructions, installation how-to's, and general safety guidelines-ideal for when your equipment requires some TLC.

Even with a sturdy structure like a Hannay's, wear and tear are a normal part of your reel's existence. Even the most durable parts and materials require annual maintenance to guarantee peak performance. Hannay knows that when your equipment fails, your productivity suffers.

This above hose reel was installed back in 2013 and has held up well due to regular and scheduled maintenance.

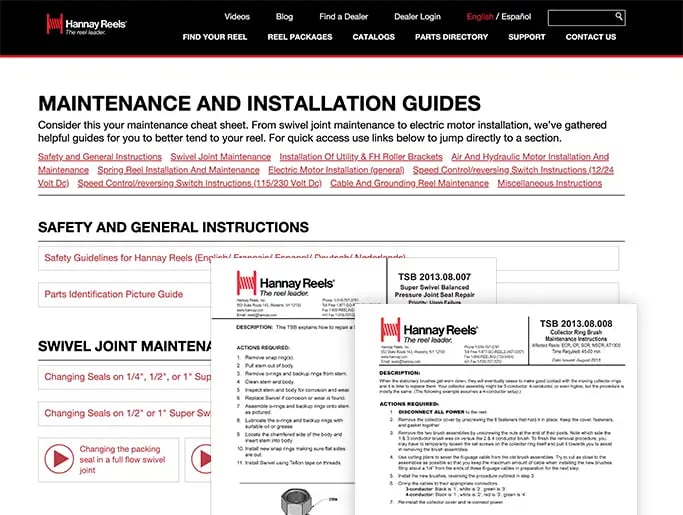

Preventive maintenance is essential for getting the most out of your reel. Hannay has prepared "Maintenance and Installation Guides" with thorough instructions for everything reels in their ongoing attempt to serve the requirements of their consumers long after the original purchase.

Installing hose and roller assemblies, greasing and changing packing seals on swivel joints, collector ring upkeep on cable reels, bearing replacement, motor setup and diagnostics, and other topics are covered. Part-specific maintenance recommendations and quick-install instructions are provided to assist you in making repairs quickly and effectively while keeping your work and personnel safe.

Hannay understands that safety is paramount in every business, large or small. Hannay builds its reels with the safety and productivity of your whole business in mind, from worksite applications to equipment handling. Each reel includes a thorough Safety Guidelines leaflet.

Hannay advises following the following general safety principles to safeguard the safety of your staff and the job site:

Inspections and routine maintenance should be performed on reel framing, discs, fluid routes, motors, and swivel joints. Give the reel a once-over monthly to ensure everything is in a serviceable state.

-

Check that all parts are clean, tight, and structurally sound.

-

Examine all of the electrical connections on motors and cable reel collector assemblies.

Examine all of the electrical connections on motors and cable reel collector assemblies.

-

Avoid exceeding the hose reel's maximum working pressure.

-

On spring return reels, use ball stops. Never let go of the hose or cable when rewinding a spring reel. In addition, never remove the cover enclosing the spring motor.

-

Avoid pinch points and exercise extreme caution when working around the chain and sprockets.

Don't let repairs and maintenance get in the way of your work. We've got you covered with everything reels, with step-by-step maintenance lessons supplied by Hannay professionals. Check out all of our resources to find out why Hannay Reels is still known as "the reel leader."

By Spray Nozzle Engineering Editor | April 06th, 2023 | Reel Tech