In the world of factories and worksites, safety and efficiency are paramount. While everyday items like hoses might seem innocuous, they can pose significant risks if not managed properly. Hoses used for various tasks, from washdown and transfer to hydraulics, beverages, and lubricants, often lie on the ground, creating a double threat: tripping hazards and potential hose damage.

The most immediate danger is the risk of slips, trips, and falls. Hoses, especially when wet or greasy, can become incredibly slippery, creating a nearly invisible obstacle for busy workers. A stumble over a hose can lead to serious injuries, impacting both the individual and the overall productivity of the workplace. Imagine a worker carrying a heavy load tripping over a hose, potentially dropping their cargo and injuring themselves or others. The consequences can be far-reaching.

The most immediate danger is the risk of slips, trips, and falls. Hoses, especially when wet or greasy, can become incredibly slippery, creating a nearly invisible obstacle for busy workers. A stumble over a hose can lead to serious injuries, impacting both the individual and the overall productivity of the workplace. Imagine a worker carrying a heavy load tripping over a hose, potentially dropping their cargo and injuring themselves or others. The consequences can be far-reaching.

Beyond the immediate safety concerns, hoses left sprawled on the ground are susceptible to premature wear and tear. The constant pressure from foot traffic, forklift movements, and even passing vehicles can cause abrasions, cracks, and internal damage. This unseen deterioration can lead to leaks, spills, and even hose bursts, posing environmental hazards and potential equipment damage. Consider the cost of replacing a burst hydraulic hose on a critical piece of machinery, not to mention the downtime and lost production associated with such an event.

Furthermore, hoses left on the floor can become contaminated with dirt, debris, and other harmful substances. This contamination can then be transferred to the fluids they carry, potentially impacting product quality and even posing health risks. In the case of food and beverage applications, for instance, contaminated hoses can introduce harmful bacteria or allergens, jeopardizing food safety and brand reputation.

The good news is that these risks are entirely preventable. By implementing simple yet effective measures, factories and worksites can create a safer and more efficient work environment. Here is our key strategy:

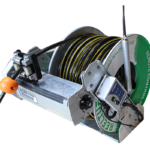

Designated hose storage: Invest in designated hose reels to keep hoses off the ground when not in use. This not only prolongs hose life, and can eliminate frequent costly hose doctor callouts, but also reduces the risk of tripping but also protects hoses from damage and contamination, Hannay spring rewind hose reels use a ratchet-lock mechanism so that when the operator is finished with the application a simple tug can wind the hose back on the reel.

By prioritizing hose safety, factories and worksites can create a win-win situation. They can safeguard the well-being of their employees, minimize the risk of costly accidents and equipment damage, and ensure product quality and safety. Remember, a seemingly insignificant hose lying on the ground can have significant consequences. By taking proactive steps, you can turn this hidden hazard into an opportunity to enhance safety, productivity, and overall peace of mind in your workplace.

By ReelTech Editor | March 26th, 2024 | Hose Reels - Cable - Industrial